Adjustable, controllable mixing with low shear rate

↘︎ Homogeneous nutrient distribution

↘︎ Higher oxygen transfer rate

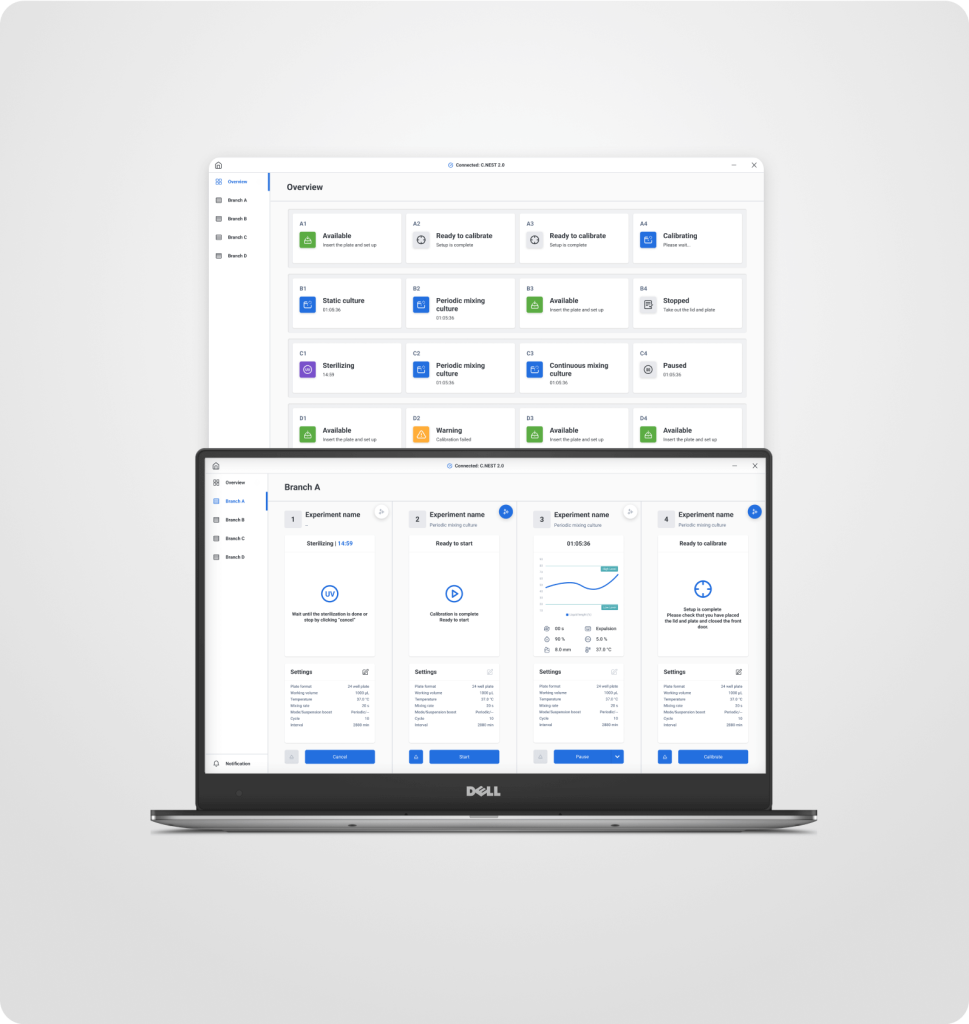

Navigate effortlessly through our user-friendly software interface, allowing for convenient control of the four incubation chambers. Control and monitor the mixing status and culture environment of your experiment.

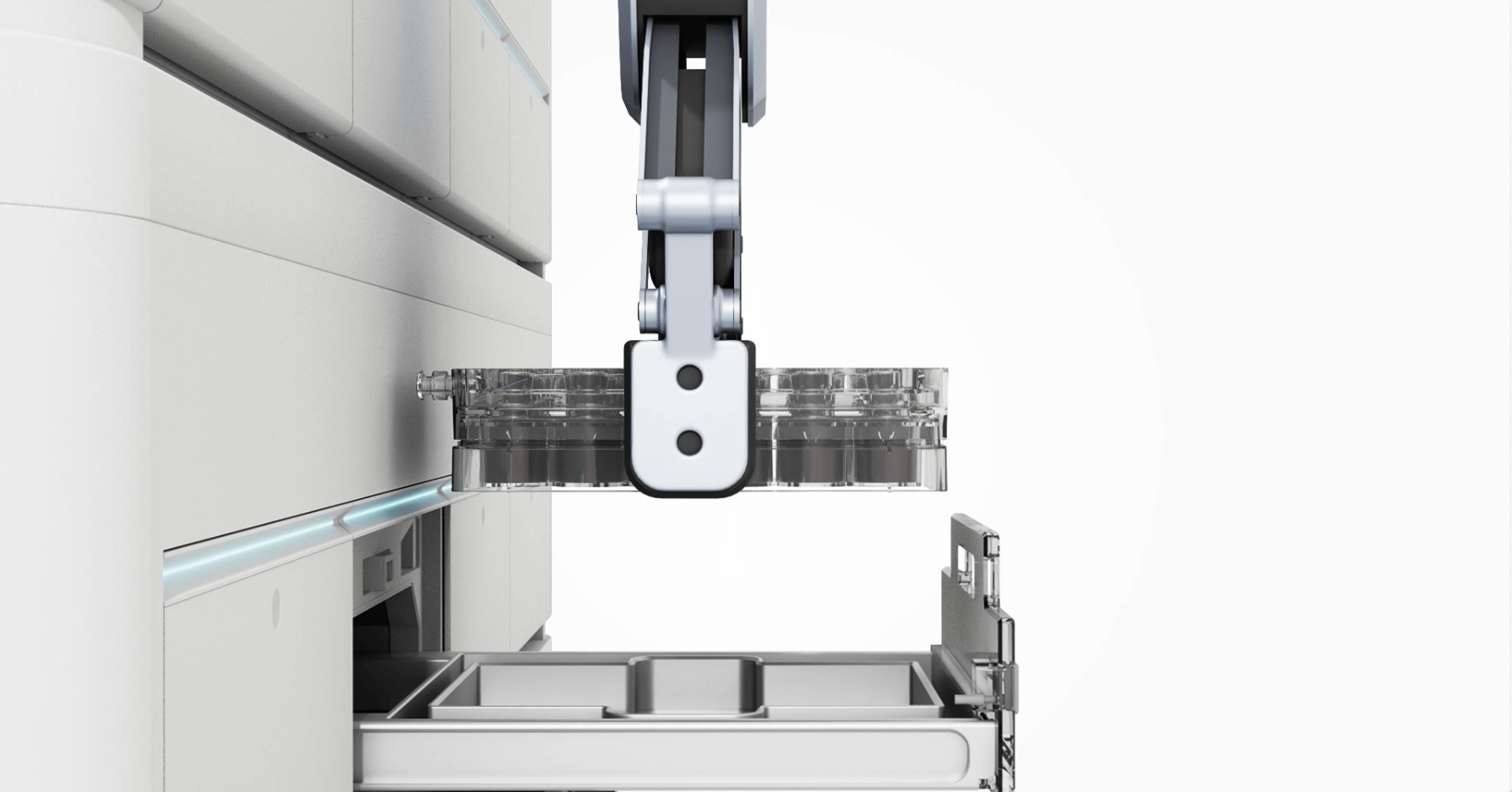

Efficiency meets innovation. C.NEST seamlessly integrates your robotic arm, supports SiLA 2.0, and interfaces with third-party scheduling software for a streamlined workflow.

| Description | Value | Unit |

| Dimensions | ||

| Width | 750 | mm |

| Depth | 460 | mm |

| Height | 190 | mm |

| Weight | 33 | kg |

| Electrical characteristics | ||

| Input voltage | 100-240 | Vac |

| Input voltage net tolerance | ±10 | % |

| Input voltage frequency | 50/60 | Hz |

| Max. input current | 5.9-2.7 | A |

| Power mains supply voltage fluctuations | ±10 | A |

| Installation category | CAT ll | - |

| Input fuse type | 250VAC, 8A, time-lag | - |

| Description | Value | Unit |

| Incubation | ||

| Temperature control range | RT+10 - 40±0.2 | °C |

| CO2 level control range | 1-20±0.3 | % |

| Humidity monitoring range | 0-100±5 (at 37°C) | % |

| Culture | ||

| Mixing rate (24-well plate) | 10-50s±5 | % |

| Mixing rate (96-well plate) | 10-50s±5 | % |

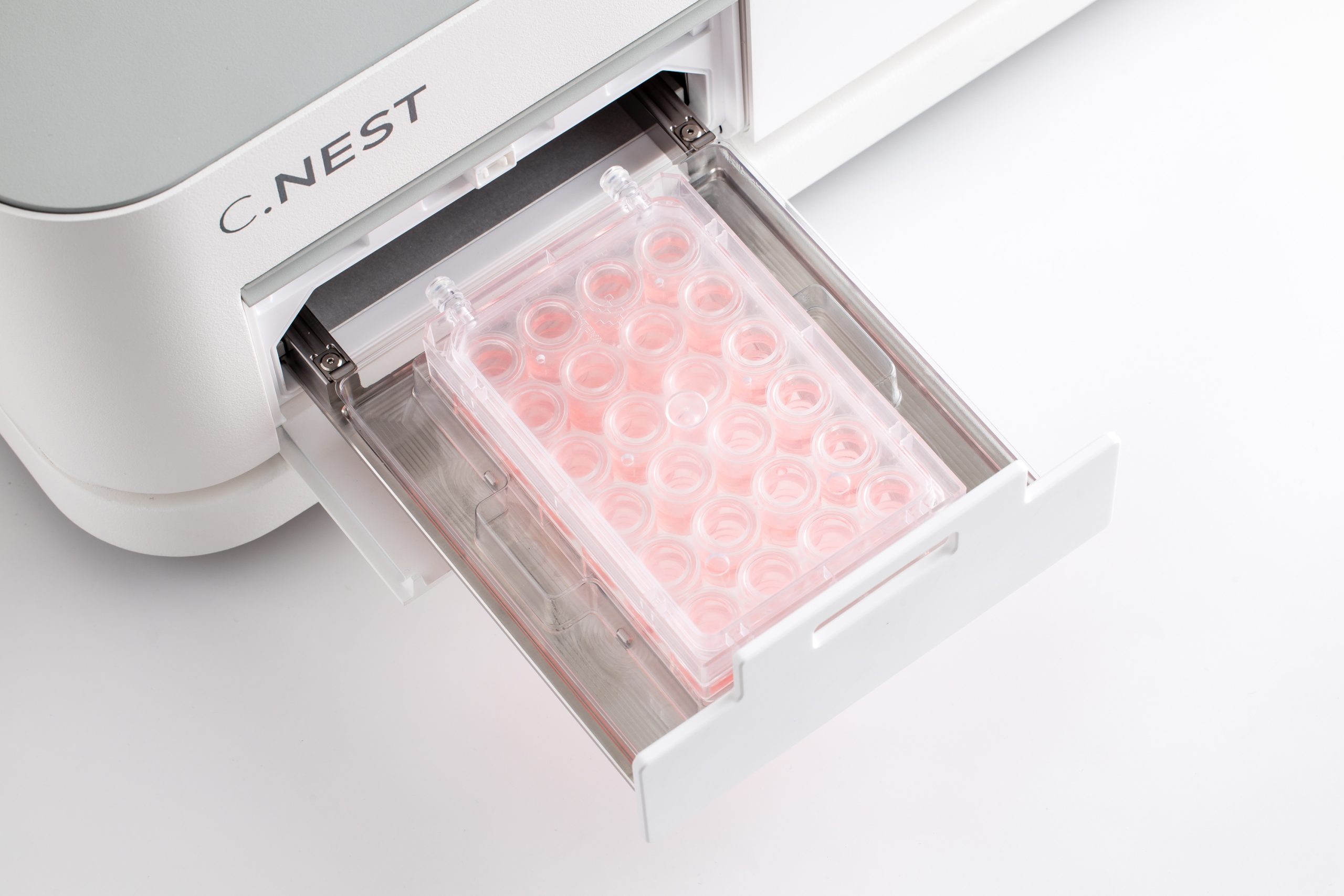

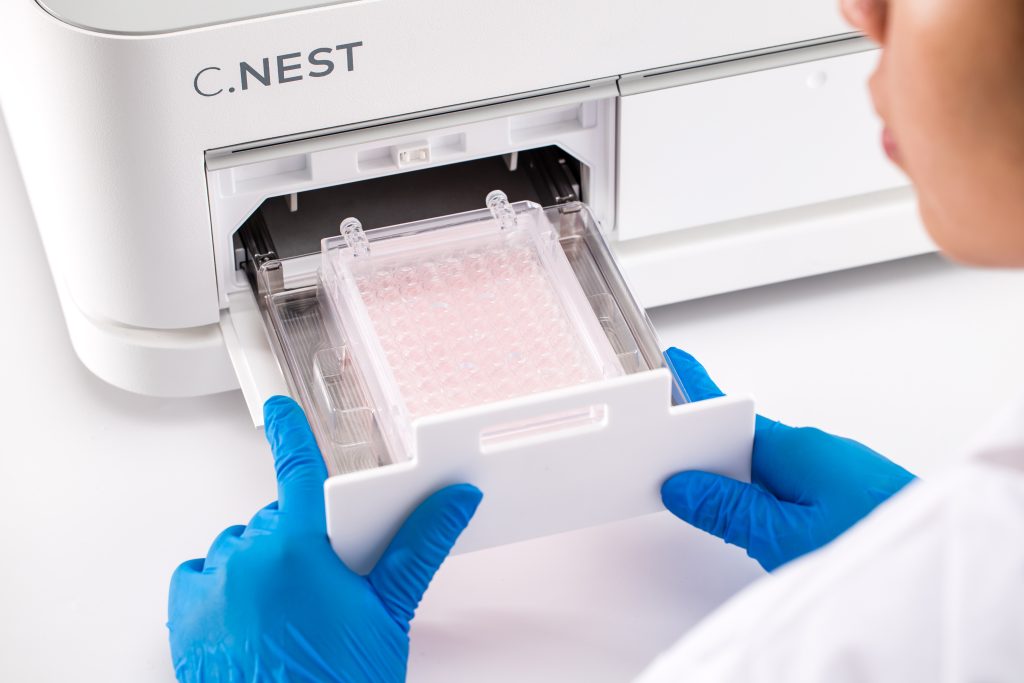

| Working volume (24-well plate) | 1,000-1,600 | μL |

| Working volume (96-well plate) | 150-200 | μL |

| Working volume (384-well plate) | 25-80 | μL |

| * Each value above is specified with one standard deviation from its mean (M±1SD) | ||

By entering your email, you agree to our Terms of Service and Privacy Statement

CYTENA BPS is a part of BICO. Our products aim to reduce the organ shortage and speed up drug development by providing accessible life science solutions that combine biology and technology, fundamentally shifting the global healthcare industry.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |